The sliding seat of the CNC drilling machine moves throughout the entire length of the bed, with a single open side. The structure is simple and convenient, ma...

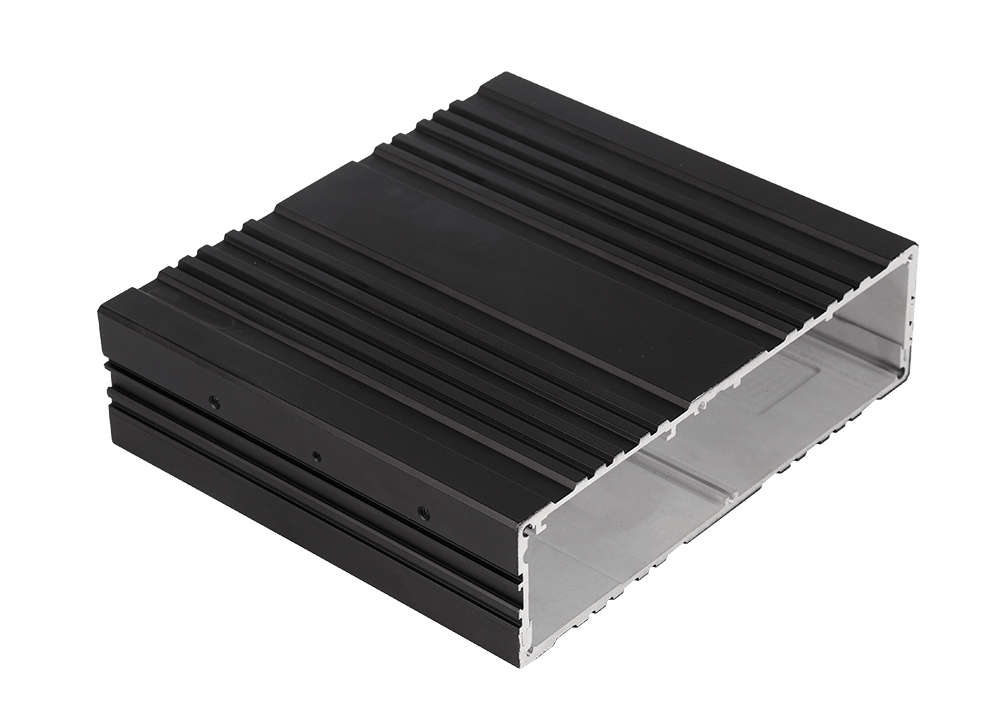

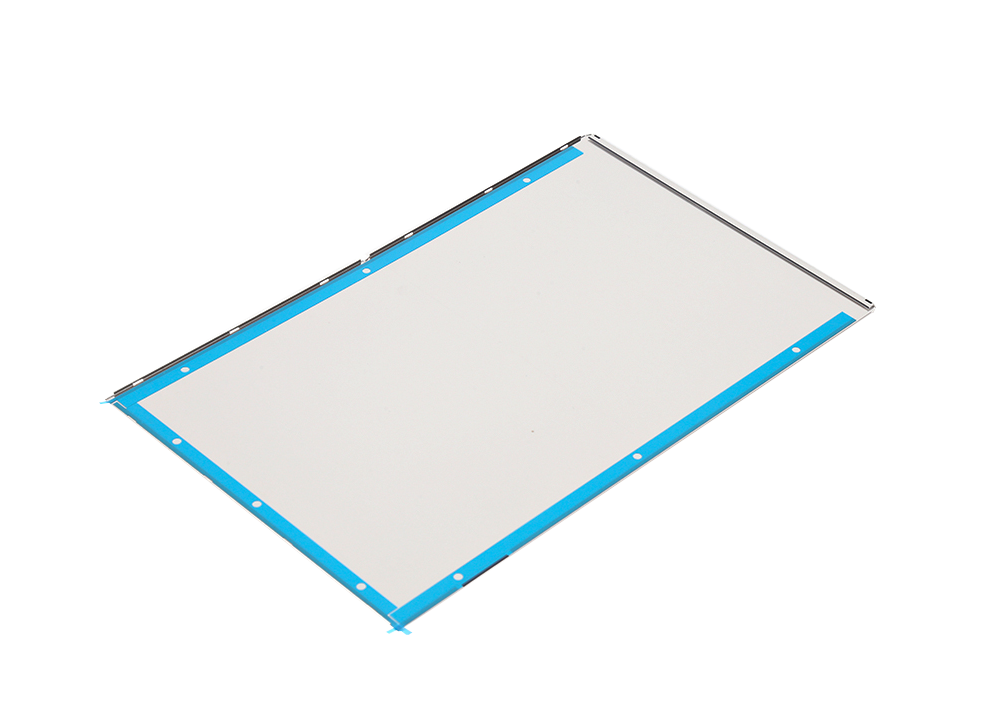

Aluminum profile processing center is a high -precision, high -efficiency industrial processing equipment, for cutting, drilling, and attack thread processing...

As people's daily life is becoming more and more modern, the use of aluminum profiles is becoming more and more common. In the production process of aluminum pr...

Machining Center: Hong Kong and Taiwan, and Guangdong are called computer gongs, which are a highly automated multi -functional numerical machine tool with knif...

The cooling and solidification speed of the disappearance of the mold tool casting is slow, slower than ordinary sand -type casting. There are three types of pr...

Powder Metallurgical and Engineering Plastics, after using these rough manufacturing methods. It can greatly reduce the amount of mechanical (xiè), and sometime...

Related News

Related News·Four factors affecting the cutting accuracy of CNC laser cutting machines ·What is the selection of cutting tools for CNC gantry machining centers? ·How can precision machining manufacturers achieve high cost-effectiveness? ·What are hardware accessories? ·CNC precision part processing manufacturers must be strict with precision requirements for precision ·The key to the improvement of high -speed processing center performance ·What are the programming skills for CNC machining centers? ·Mechanical angle analysis CNC carving and milling machine, CNC milling and high -speed milling ·Reasons for insufficient air pressure in the profile processing center of a large gantry drilling ma ·What are the standards for CNC machining of aluminum alloys?