Time:2022-11-15 Preview:

There are many kinds of metal die-casting processing. In addition, the specifications and sizes are different, some are simple, and some are complex. However, both complex and simple workpieces play an irreplaceable role in the application of various equipment. The die casting of five parts usually uses various raw materials to purchase, and then through different processing processes and steps to complete the formula workpiece.

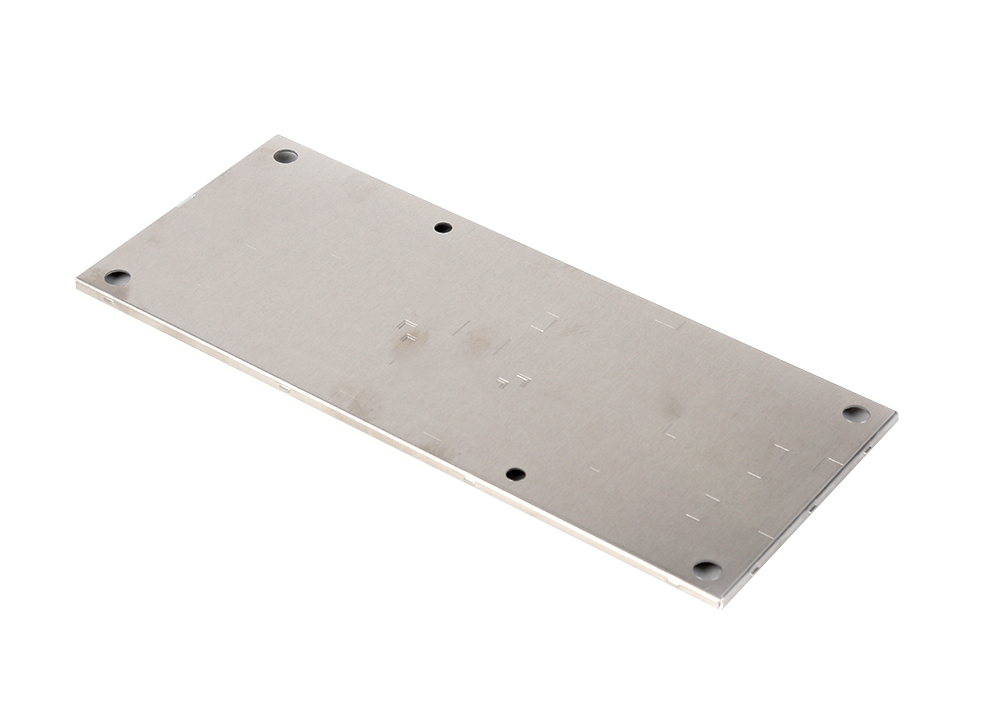

1. Sheet metal: the sheet metal mold is fast in production, low in cost and short in delivery time. Sheet metal has become a good substitute for the internal structural components of injection molded plastic, because it provides greater flexibility in the early stages of the design process.

2. NC machining: NC is an economic and effective solution to process complex shapes and strict zero tolerance parts. NC precision machining can process almost any shape

3. Turning: Turning process includes cutting, end face, thread, forming, drilling, knurling and boring. For the surface processing of hardware parts, turning is usually a good choice if you want to have a precise bearing surface on a complex machine.

Related News

Related News·Do you know how to test the accuracy of the Longmen milling machine? · CNC Machining Machining, which is effective to reduce production costs ·stable product quality, reasonable layout, reduce waste and improve material utilization. ·The advantage of the high -speed machine of the processing center is ·What are the processing technology of precision parts? ·CNC composition ·Machining method of non -elevation precision parts for hardware processing plants ·CNC technology - a precise leader in the manufacturing industry ·The machine tool installed at high -speed carving and milling machine is in place ·How to reduce the noise of precision part processing manufacturers?