Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

1. Precision hardware processing Customized surface scratch problemReason analysis: ① The surface of the raw material is not smooth. ② The curved radius of the ...

Inspection and adjustment of Hardware Pouring Molding Model: Playing molds should be checked and maintained regularly to reduce the formation of convex concave ...

1. Carbon tool steelT8A, T10A and other carbon tool steels are widely used in high -quality small hardware processing molds, which have the characteristics of g...

The technical requirements of metal stamping parts processing should be developed in the direction of complex structure, increased size, more parts with related...

Hydraulic forming is a method of using liquid pressure instead of rigid punch or mold stamping metal boards. CNC stamping hardware processing can perform many s...

Hardware spring plate production is a special process that processing materials (metal or non -metal) into parts through cold pressure processing of stamping mo...

Related News

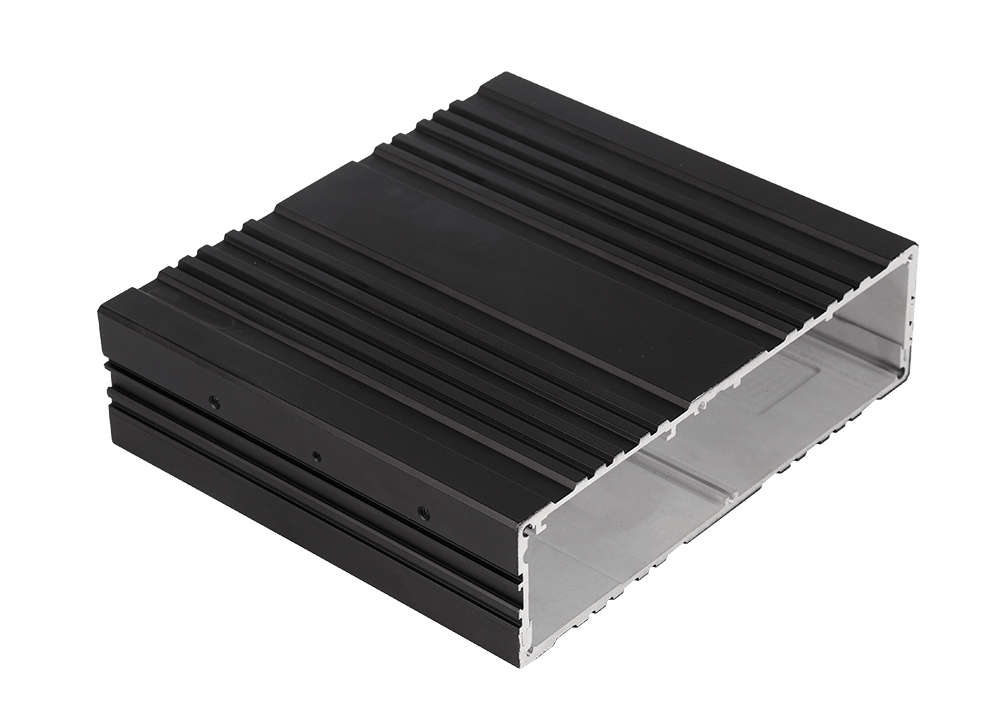

Related News·Medical parts also have high requirements for medical spare parts shell processing. ·But don't underestimate the processing process of the hardware processing plant ·The advantages of face recognition shell aluminum alloy material ·What are the advantages of CNC CNC processing ·Environmental inspection conditions for metal die casting? ·What factors are the durability of precision hardware processing molds? ·Universal die-casting aluminum alloy shapes the sturdy building materials of the era ·What are the measurement methods for hardware processing accuracy ·Is there any way to prevent corrosion after processing of precision hardware parts? ·CNC system