Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

1. Compared with the previous measuring machine, the maximum driving speed has increased by 40 times to 200mm/s. It can move at a high speed to achieve multi -a...

That is, M function-the function used to instruct the machine tool auxiliary operation, that is, the instruction of the machine tool and its auxiliary device. S...

01: Point -to -point shift function, the CNC spark machine can realize the shift of the point -point point -to -point point point. Just select the axial input v...

1. Preliminary steps of CNC lathe processing first determine the process requirements of the parts and the batches of the processing workpieces, and prepare the...

Shaft control function: This function refers to the number of axis that can be controlled by CNC and at the same time. There are moving shafts and rotating shaf...

1) The sampling speed of the current ring circuit will be improved, and the improvement of the current control is added to reduce the temperature rise of the mo...

Related News

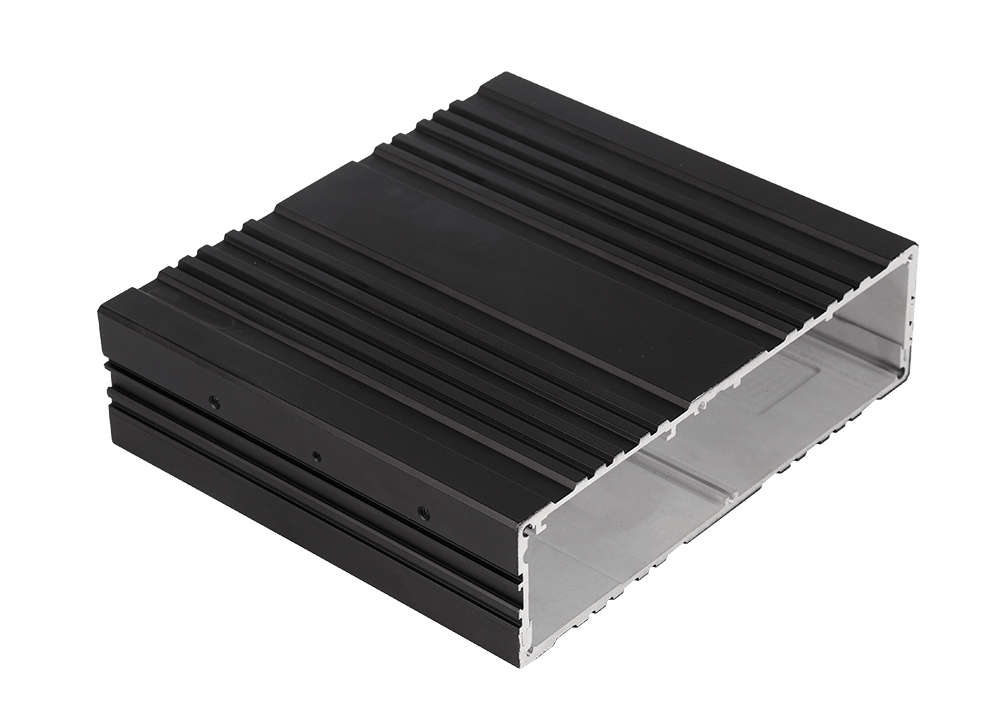

Related News·CNC machining techniques for aluminum casing ·CNC parts processing process process process is excessively decentralized ·CNC processing comparison of the advantages of 3D printing ·Carving and milling operating method ·What are the specific methods of precision machining ·What are the measurement methods for hardware processing accuracy ·Analysis of the reasons for the inaccurate precision of metal stamping parts of stamping metal proce ·The main role of the connector contact plating using the electroplating process ·Six points you need to know about the processing performance of precision hardware accessories ·Change the electronic computer's CNC machine tool program process