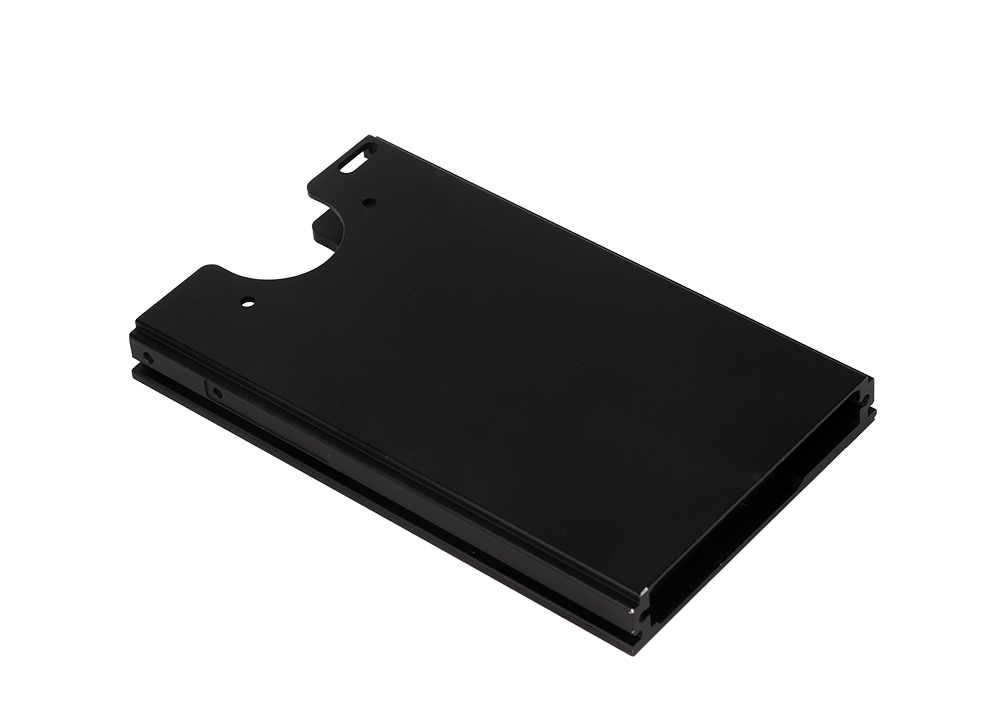

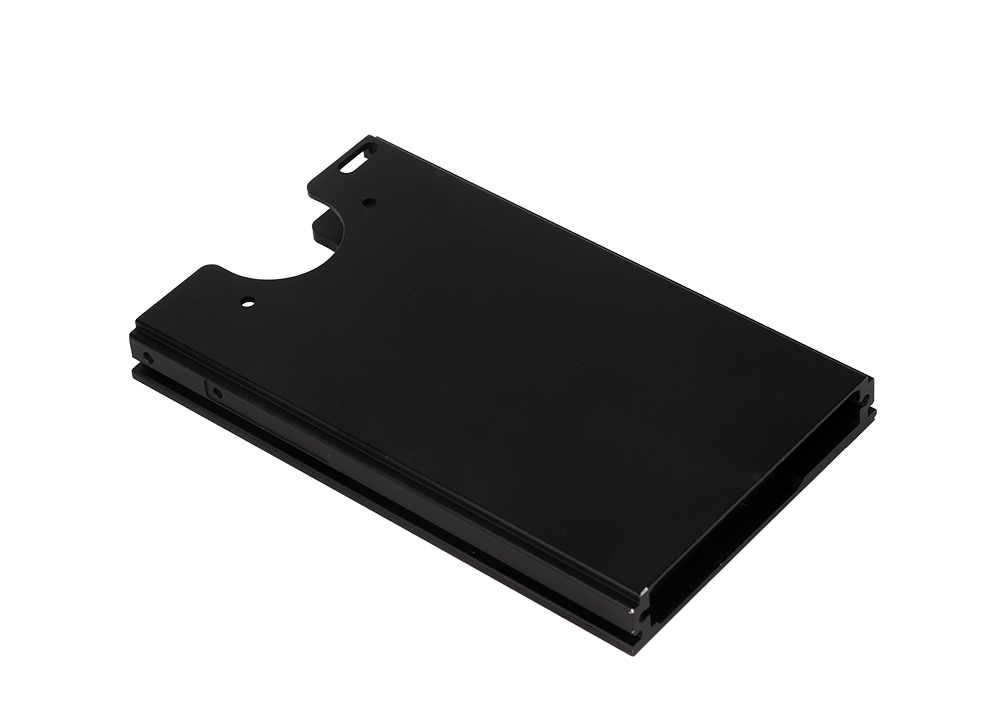

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

1. The placement of high -speed carving and milling machines or beds must be stable and strong.2. Tort the random ground screw in the ground screw hole in the b...

1. The operator must be familiar with the general performance, structure and transmission system of the machine tool, and it is strictly forbidden to use super ...

1. Overall: The knife and the tooth are made into one.2. Overall welding tooth type: The blade tooth is made of hard alloy or other wear -resistant knife materi...

1. Digital control (NC) It is a technology that uses digital pulse to send instructions to a work process and authentic control.2. Numerical Control System ...

1. Continuously enterPress F1 to select the manual continuous feed method in the manual way, and then the continuous feed feed can be achieved by entering the a...

The machinery of the machine tool is divided into two parts, the movement part and the non -moving part: the workbench, skateboard, cross flower table, etc. are...

Related News

Related News·Process flow of hardware painting equipment ·Materials of Hardware Die Casting Mold ·How to choose the Longmen Processing Center (Longmen Milling Bed)? ·Correct operation of a 15 meter single arm CNC drilling machine · CNC Machining Machining, which is effective to reduce production costs ·How to Reduce Errors and Improve the Precision of CNC Lathe Machining ·What are the drawbacks of stainless steel processing ·Analysis of the core role of humidity testing on connectors ·Machining process of aluminum alloy type thick wall parts ·CNC auxiliary function