Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

Non standard automated mechanical design services have the following characteristics:1. Emphasize the principles of design standardization, modularization, and ...

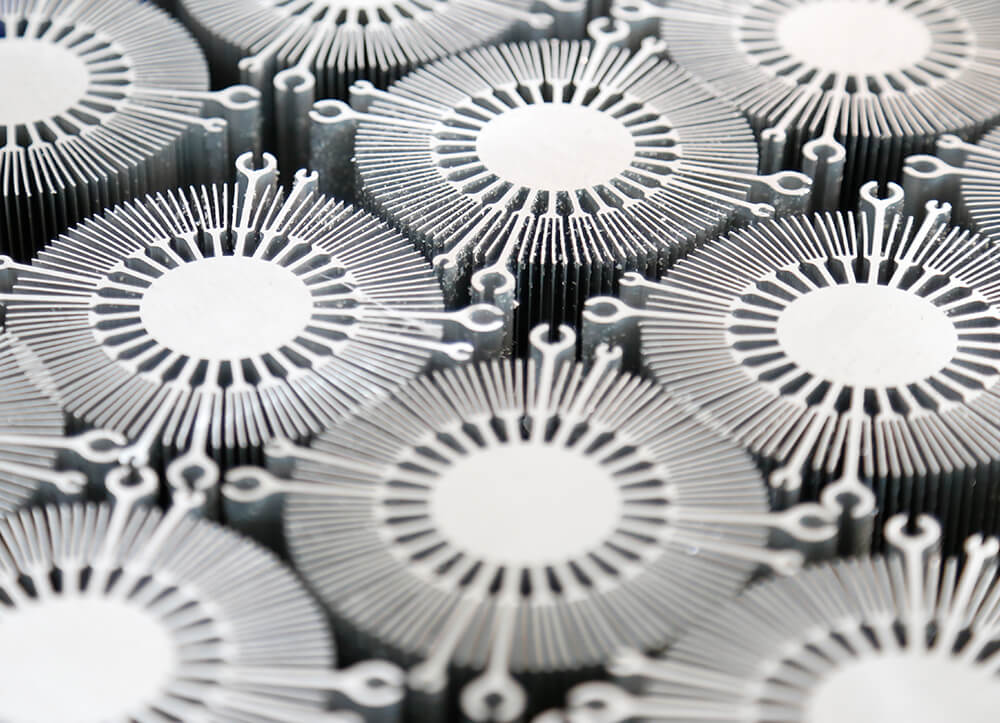

In recent years, the overall technical level of precision hardware components has rapidly improved, and a large portion of high-end and high-quality machinery h...

CNC machining precision parts, customers care about the processing effect of the product, and new product research and development or exhibition will bring unex...

Installing a good set of casting mold shells not only requires good stamping mold standards and high-precision manufacturing processes, but also requires "...

1. Must have accurate design drawingsPrecision hardware processing is the processing of some small diameter hardware components. Therefore, hardware processing ...

The precision hardware processing steps are as follows: according to the production requirements, the steel material must be ordered from the raw material suppl...

Related News

Related News·What are the main factors affecting the quality of metal powder spraying ·The advantages and work content of CNC ·What are the requirements for the storage environment of aluminum alloy castings ·Analysis of the cause of metal stamping mold explosion ·The difference between high -speed drilling processing center and processing center ·Correct operation of a 15 meter single arm CNC drilling machine ·Remember the practical knowledge of these aspects ·CNC composition ·Several sets of commonly used instructions in CNC machining centers ·What are the advantages of CNC precision parts processing