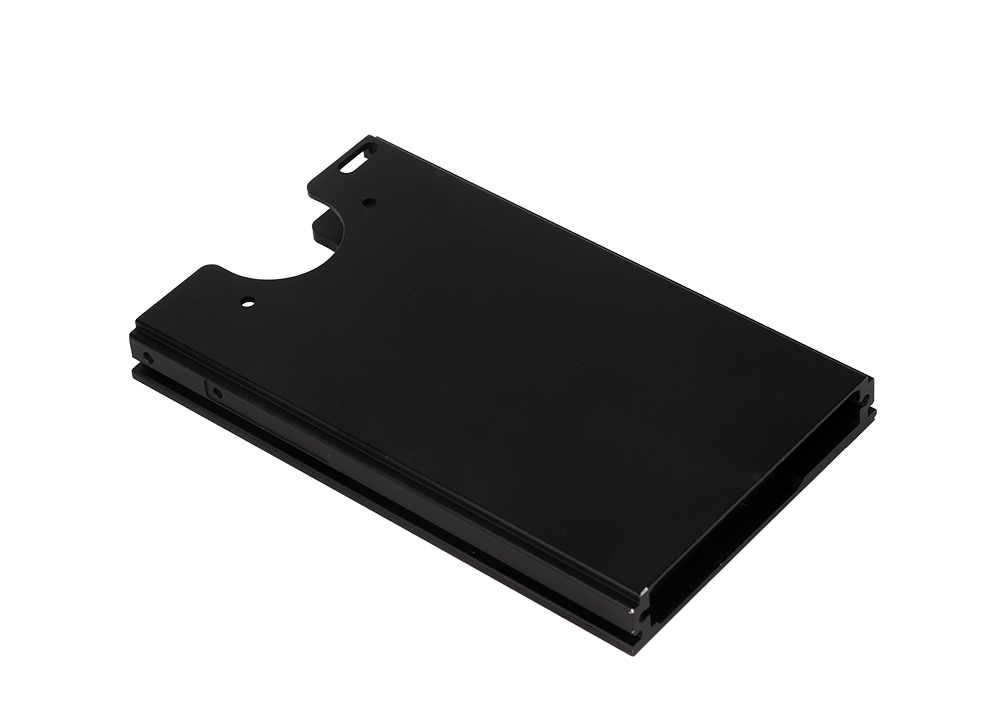

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

The cutting process can be roughly divided into turning, milling, and center tooth cutting (end face cutting of drill bits and end mills, etc.). The cutting hea...

(1) The centralized sorting method of cutting tools is to divide the processes based on the tools used, and use the same tools to process the parts. Use two kni...

1. The precision hardware parts processing mentioned earlier is to process some small diameter hardware parts, so the design drawings of this product need to be...

CNC is the abbreviation for OMputer Number Control. As a direct means of computer numerical control, it is widely used as a machining process in manufacturing, ...

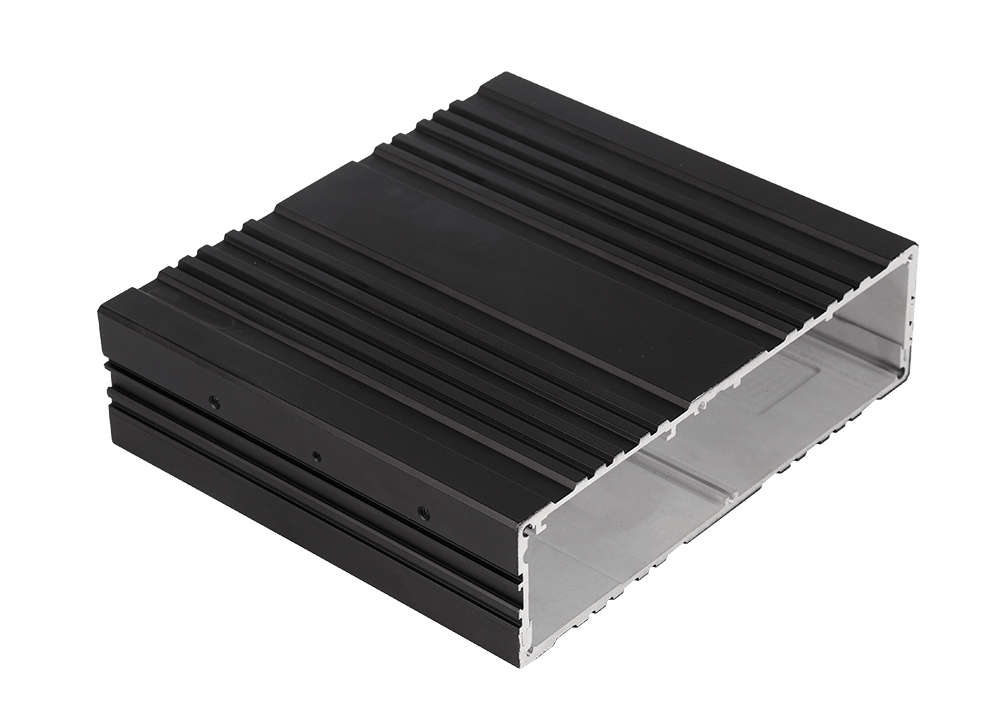

With the rapid development of industry, more and more mechanical processing manufacturers and industry users have higher requirements for product accuracy. At t...

1. Use the simulation display function of CNC machining centerUsually, more advanced CNC machining centers have a graphic display function. When inputting a pro...

Related News

Related News·Prevention of Deformation of Automobile Hardware Parts ·What are the faults of the CNC lathe processing union ·High -precision hardware processing surface treatment technology ·Key reasons and preventive measures for surface starvation caused by stamping parts ·What are the tips for the core of CNC processing to prevent the knife from hitting a knife? ·CNC processing ·Hardware processing operation steps ·Mold carving and milling machine characteristics ·Range of hardware accessories ·CNC processing manufacturers share CNC processing.