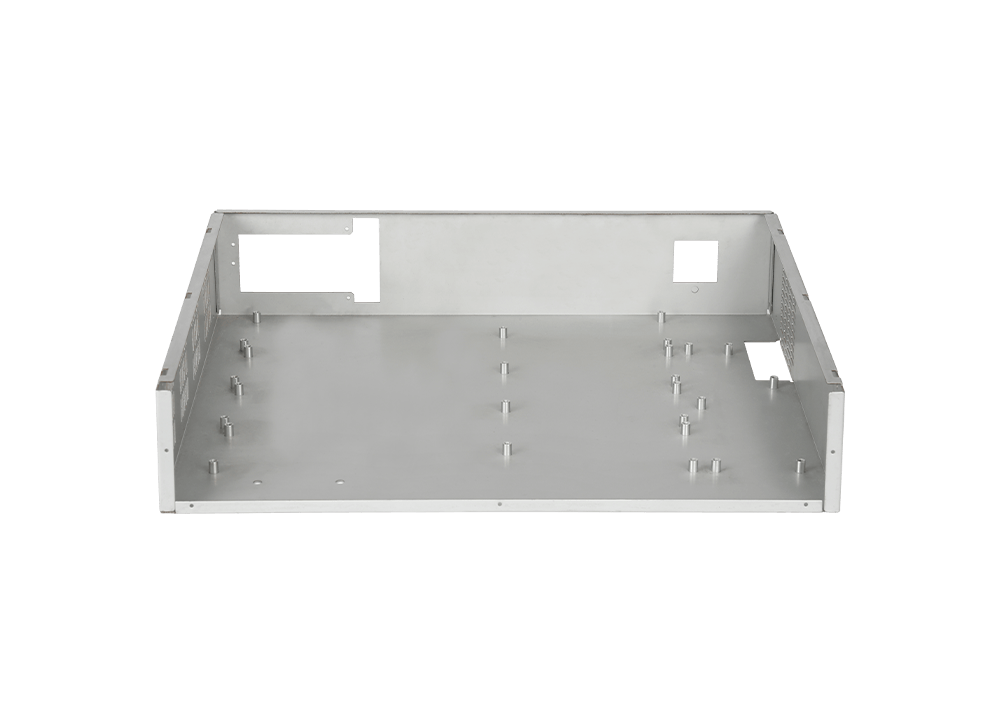

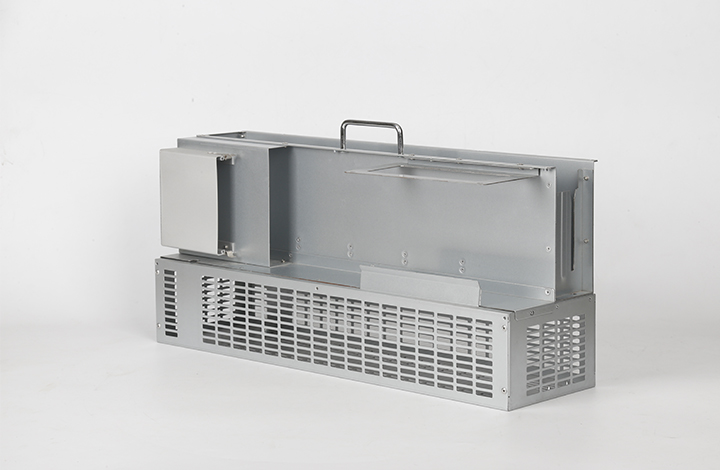

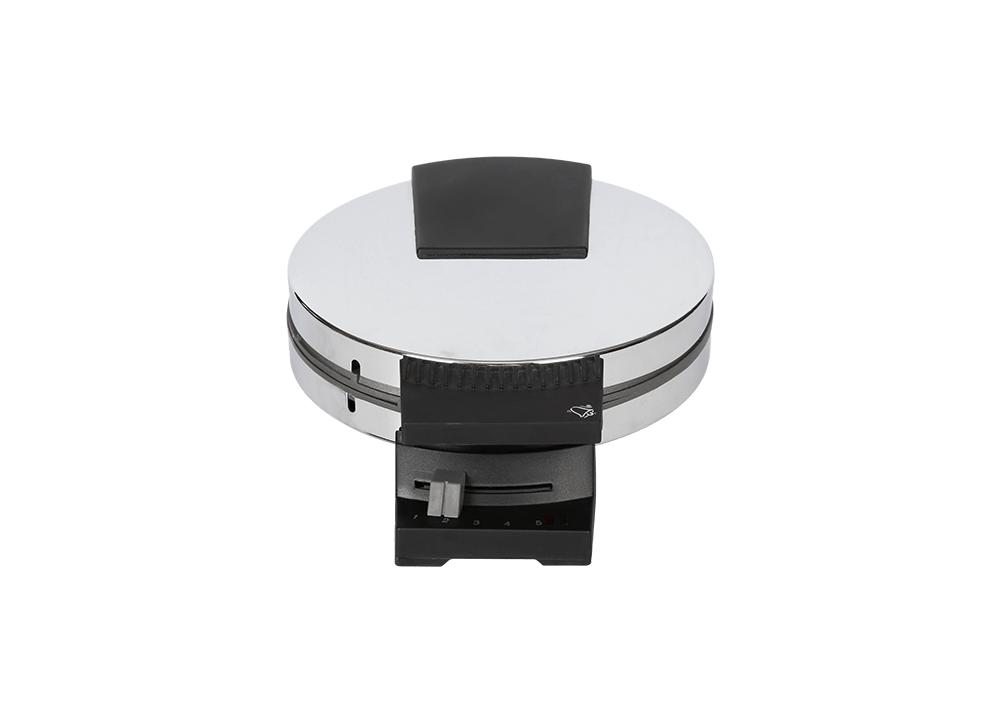

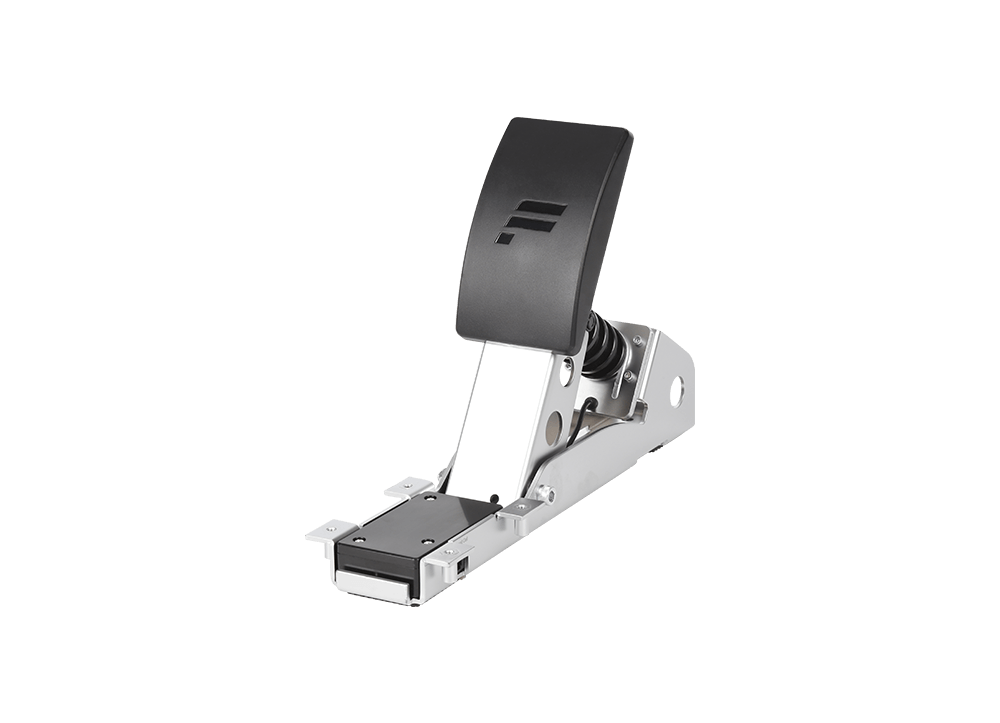

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

1. The advantages of automatic lathe processing1. Because the five knives and two tail axes of the machine can work at the same time during processing, the spee...

1. Classification according to process use:1. General CNC lathe processing. This CNC lathe processing is the same as the traditional normal lathe processing. CN...

1. Don't change the component by feeling. Some maintenance personnel did not determine a certain part of the faulty part, but they felt bad, they should be repl...

Because the five knives and two tail axes of the machine can work at the same time during processing, the speed of the machine tool processing parts is 4-6 time...

I. Accurate drawing design; hardware processing is the processing of a small amount of metal parts, so the design drawings of this product must be accurate, and...

First, running and wear is the wear of mechanical under normal load, speed and lubrication conditions. The development of wear generally has a slow development,...

Related News

Related News·The difference between engraving and milling machines, engraving machines, and machining centers ·How much do you know about aluminum profile processing? ·CNC's functional function ·The composition and characteristics of the CNC machine tool ·Tool selection and use in machining centers ·Future Development of Metal Die Casting ·CNC processing process should be paid attention to ·Riveting process of stamping hardware processing ·CNC processing technology, although relatively highly automated technology ·Which type of part processing requires CNC processing technology