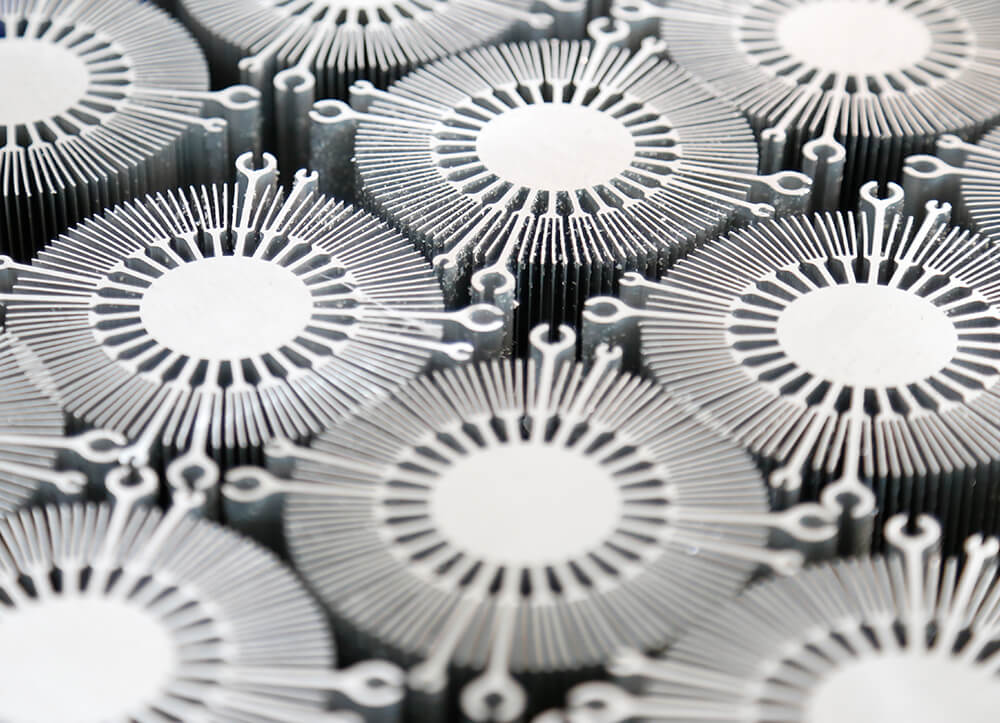

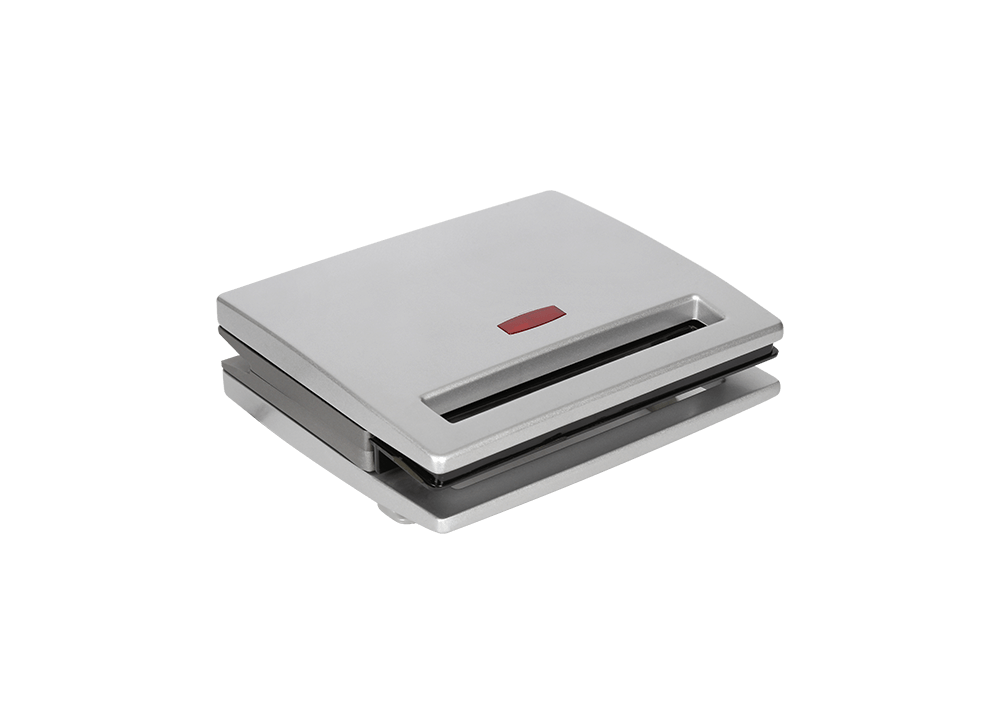

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

The high -speed drilling processing center, also known as drilling aircraft, is a high -speed CNC machine tool that has been popular in recent years. It is ma...

The so -called five -axis processing here refers to a machine tool with at least five coordinate axes (three straight coordinates and two rotating coordinates)....

For mold manufacturers using multi -axis machine tools, the development of CNC programs that make full use of these machine tool functions may be challenging. T...

The processing method of CNC workpiece surface first depends on the technical requirements of the processing surface. However, it should be noted that these tec...

I. CNC processing company introduced that the operator must be familiar with the basic knowledge and maintenance methods of structure, performance and transmiss...

According to the CNC processing manufacturer, the benefits of using CNC machining workpieces, we have a deep understanding of the operation and programming of t...

Related News

Related News·Introduction to the Application Fields of Small CNC Machining Centers ·Requirements for CNC parts processing ·CNC Precision Hardware Parts Processing Operation Process ·The tool radial runout of CNC milling machines produced by CNC computer gong manufacturers ·How to solve the defects of metal die castings? ·Aluminum alloy CNC processing process ·Operation and maintenance requirements of hardware die-casting machine ·CNC processing structure ·Can precision machining be done with any material ·How to improve the service life of CNC gantry drilling and tapping machine