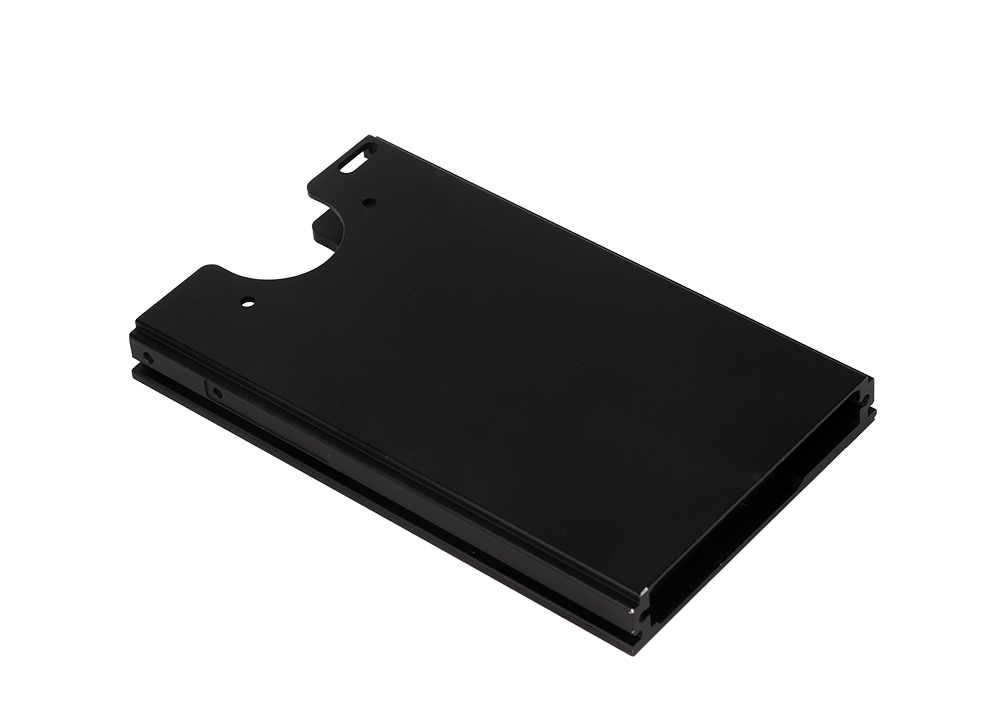

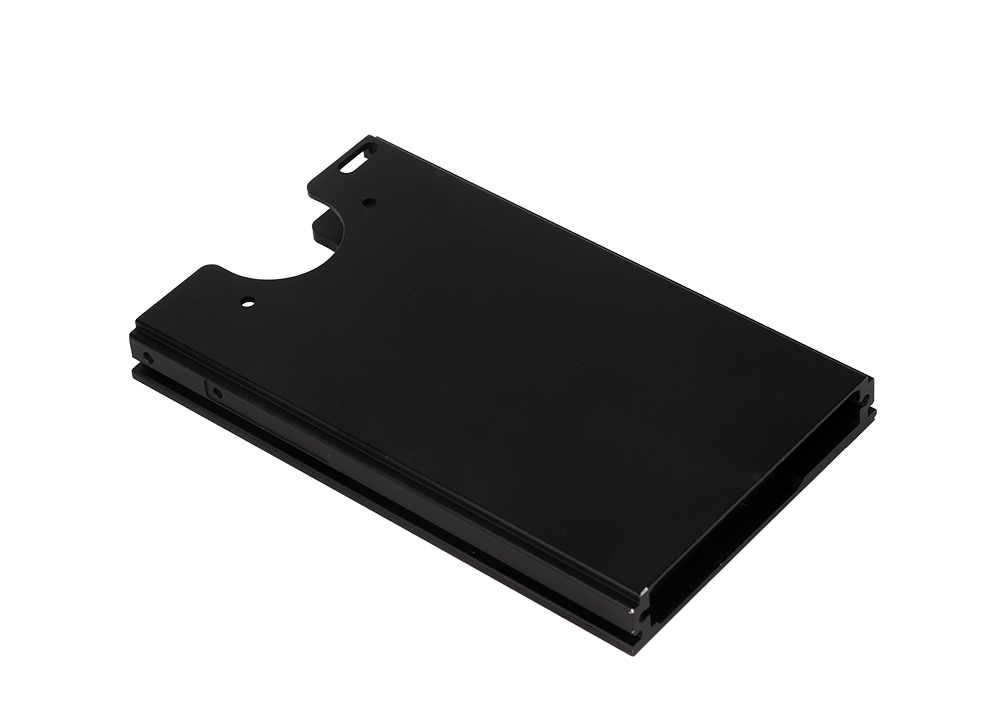

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

Due to the high technical content of the processing center, it is more complicated, operating than ordinary machine tools, and shall be operated strictly in acc...

In modern society, the use of machine tools is already very common, especially in recent years, it has pushed out several high -precision machine tools. But bec...

The horizontal processing center refers to the processing center of the workbench and the main axis as a parallel state. The horizontal processing center usua...

Milling processing cutting amount includes the main axis Motor speed, feed speed, back -eating knife volume, and side eating. The amount of feed processing of m...

When the appearance of metal cutting processing workpiece, the appearance roughness is mainly due to the effects and influence of several elements, physical fac...

First, learn to work up and down. Living is also demand skills, and this accumulation of demand experience. Generally, the workpiece of processing will be clamp...

Related News

Related News·How to Reduce Errors and Improve the Precision of CNC Lathe Machining ·The accuracy requirements for stamping hardware processing for stamping mold components ·Correct operation of a 15 meter single arm CNC drilling machine ·Mold carving and milling machine characteristics ·What do we need to pay attention to during mechanical processing? · How to Improve the Service Life of Large CNC Drilling Machines ·What are the common problems of TV hardware powder spraying? ·Use characteristics of non -standard part processing Non -standard part processing equipment is also ·Production and processing flow of small household appliances · How to remove the mechanical parts processing