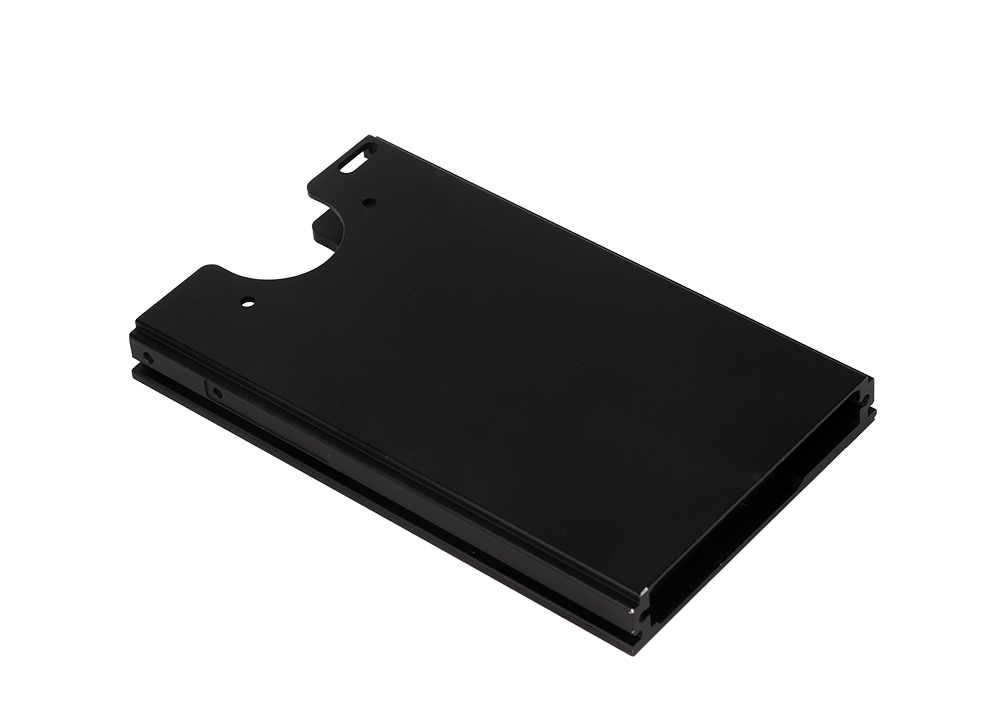

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

1. Appearance inspection:Check if the machining of machined parts meets the requirements of the drawings.2) Check the appearance of the machined parts of the ma...

During the machining process, the factors that affect the surface quality of the workpiece include cutting conditions, cutting speed conditions, cutting speed, ...

The development of CNC machining programs can be roughly divided into two steps. Firstly, develop a process route for processing parts, and then determine the p...

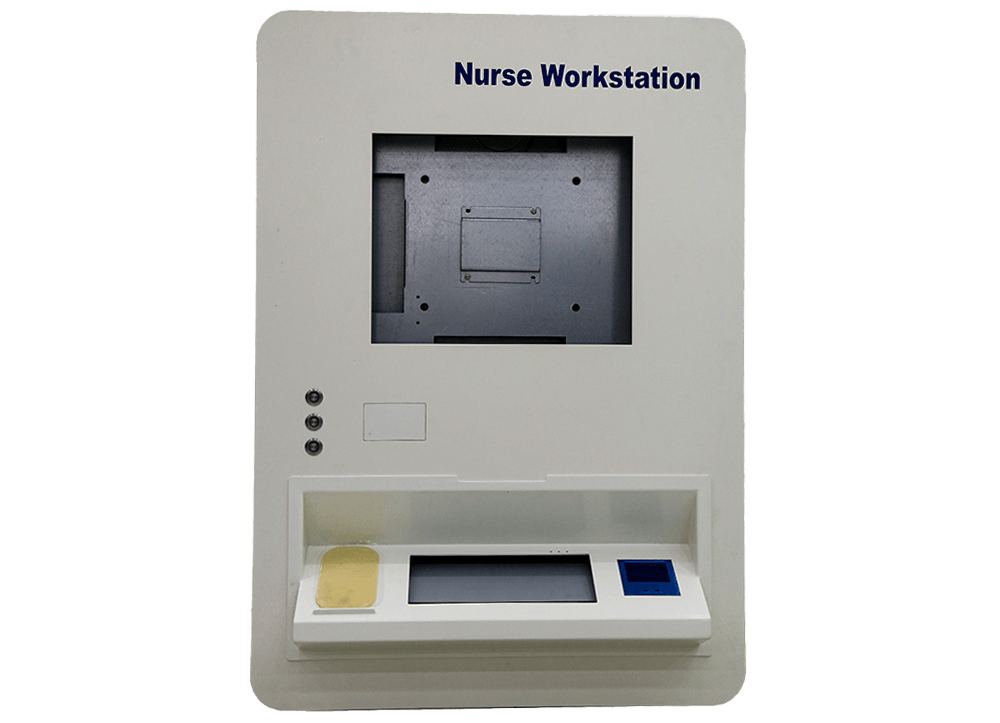

(1) Easy to operate, reduces back and forth movement, and avoids unnecessary bending and toes.(2) Accurate and reliable positioning to prevent misoperation caus...

(1) To ensure machining accuracy, rough machining and precision machining are separated. Due to the large cutting amount during rough machining, the workpiece h...

1. Reduce initial errors. Improve the geometric accuracy of the machine tool used for machining parts, improve the accuracy of fixtures, measuring tools, and to...

Related News

Related News·Pay attention to the four main points of using the horizontal processing center? ·How to align the CNC large highlight machine for profile machining center ·What are the tips for using screws of stainless steel hardware processing manufacturers? ·Analysis and elimination of common faults in high-speed electric spindle · How to Choose a Suitable CNC Milling Machine for CNC Gantry Drilling and Milling Center ·Basic technical requirements for stamping hardware processing! ·What are the contents of process analysis for part drawings in CNC machining? ·Key reasons and preventive measures for surface starvation caused by stamping parts ·CNC composition ·Several Polishing Methods of Hardware Die Castings