Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

The machining of CNC precision parts requires the smoothness of the workpiece and the requirements of the cutting tool. Before machining CNC precision parts, a ...

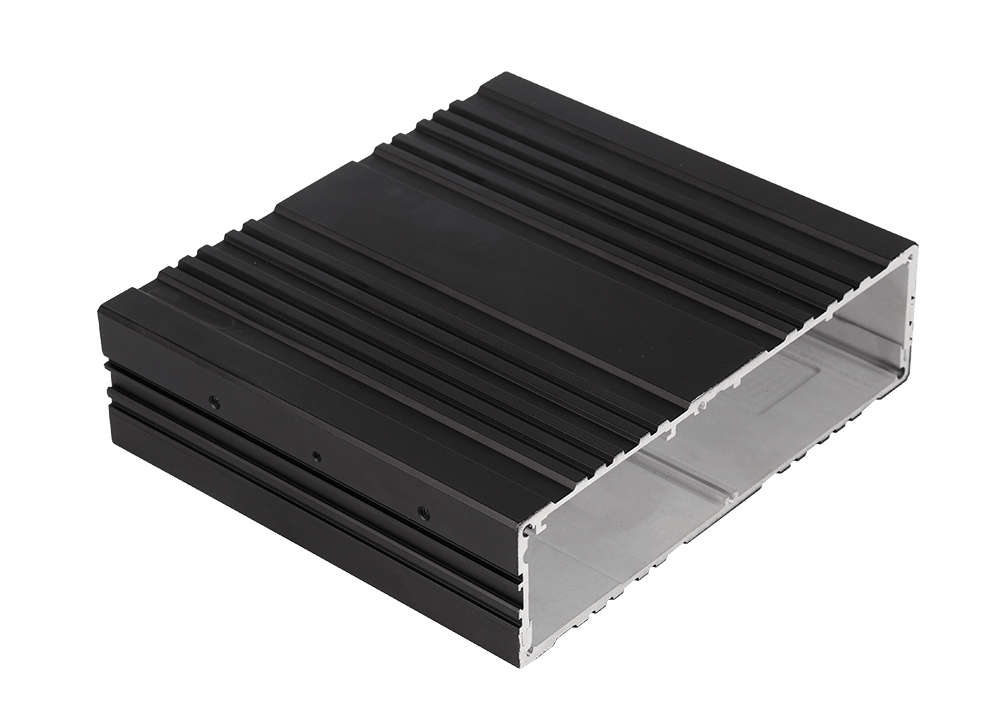

Nowadays, many customers have a significant demand for CNC precision parts processing. In the process of new product design, precision parts processed from alum...

Have you ever understood the development background of CNC lathe machining? Some large aviation factories are equipped with hundreds of CNC machine tools, mainl...

What is the five axis machining of CNC machining? According to ISO regulations, when describing the motion of CNC machine tools, a right-handed Cartesian coordi...

What are the principles for selecting cutting parameters for CNC lathe machining/CNC machining? Mainly selected based on the machining accuracy and surface roug...

What are the causes of deformation and cracking in precision machining? In fact, the reasons for machining deformation and cracking are multifaceted, such as ma...

Related News

Related News·CNC engraving and milling machine manufacturers' maintenance knowledge for CNC engraving and milling ·One of the key factors of the correct use of aluminum alloy CNC processing equipment ·The main role of the connector contact plating using the electroplating process ·Rules for safe use of CNC machining centers ·What are the factors for the wrinkling of precision metal stamping parts of non-standard precision h ·What causes the failure of metal die casting die ·The Gold Standard for CNC Processing in Modern Manufacturing Industry ·CNC precision machine processing ·Choose the basis for the selection of rough selection during CNC processing ·How to choose the original position of injection molding mold custom processing workpiece