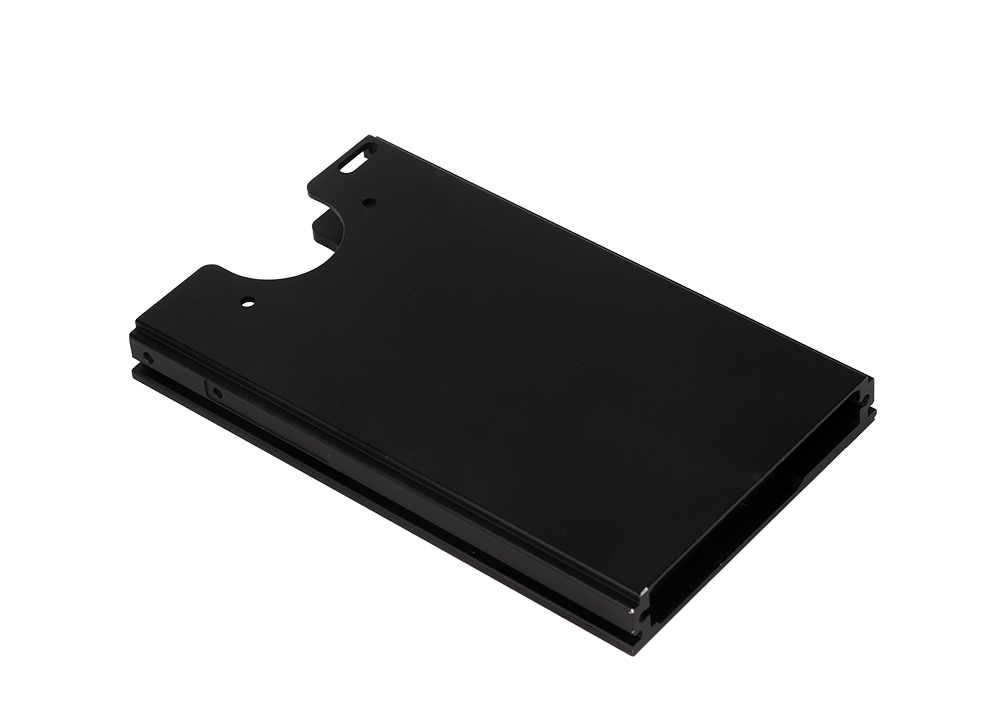

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

Horizontal machining centers can be used for precision machining of aerospace, automobiles, internal combustion engines, household appliances, and general machi...

1. High rigidity, heavy cuttingAll use resin sand wear-resistant castings, strong and tough bones, oversized columns, wide and low seats, and honeycomb structur...

The guide rail of a typical lathe used to be a hard rail. The hard rail was obtained through heat treatment, grinding, and scraping, resulting in a long product...

1. The primary basic components such as the base, sliding seat, workbench, column, and spindle box are made of HT250 cast iron; The base is a box structure, and...

Precision machining/non-standard part processing - First of all, we know that non-standard parts are proposed relative to standard parts, so before understandin...

The stainless steel customization process of CNC machining relies on more than ten years of experience in stainless steel customization processing, semiconducto...

Related News

Related News·Precision Hardware Processing Factory Data Analysis of the Industry of Industry ·CNC lathe processing must know about the relevant knowledge ·Where is the gap between the domestic processing center? ·How to repair problems in metal die casting? ·Hardware accessory processing process ·There are several processing methods for connecting network switches ·Detailed introduction ·CNC processing structure ·Aluminum profiles have light and color difference treatment methods ·Basic knowledge of CNC milling machine programming stated in the machining center