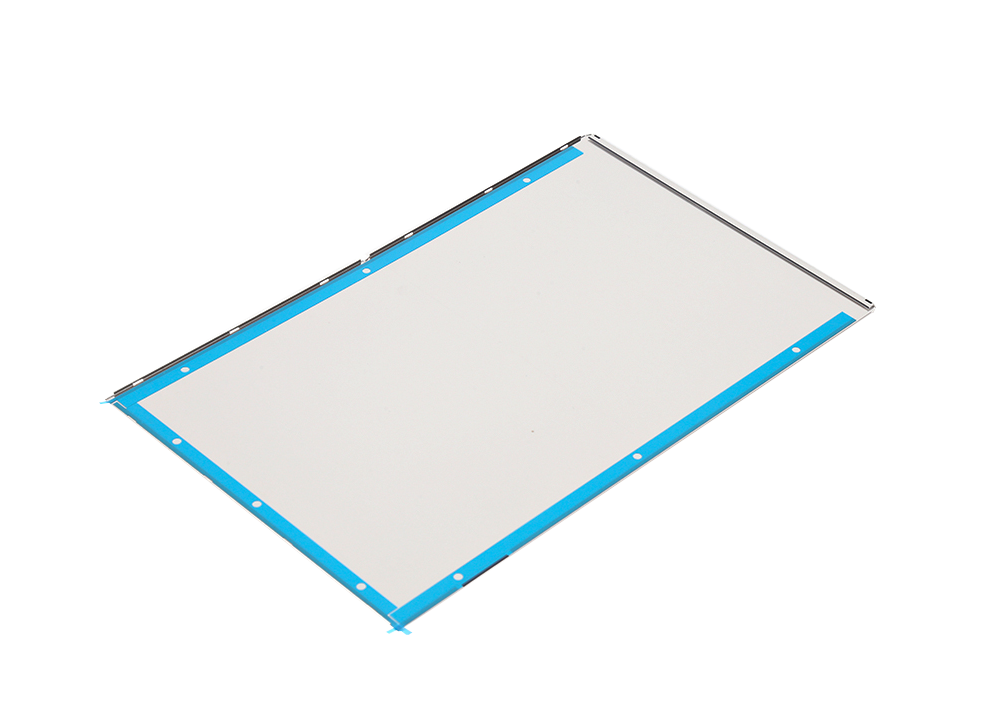

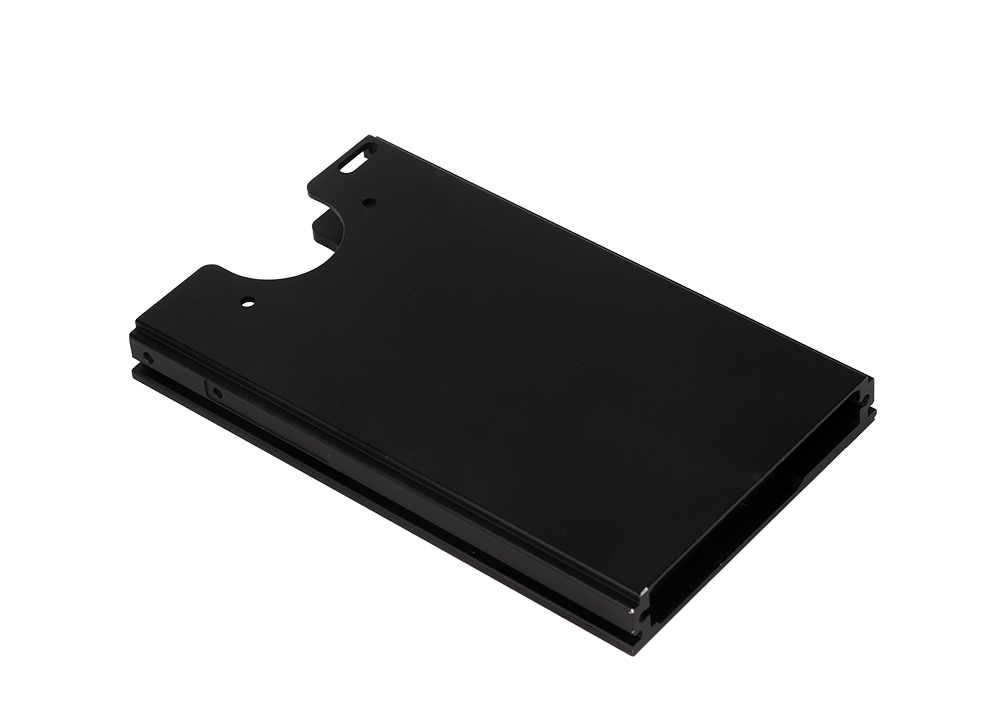

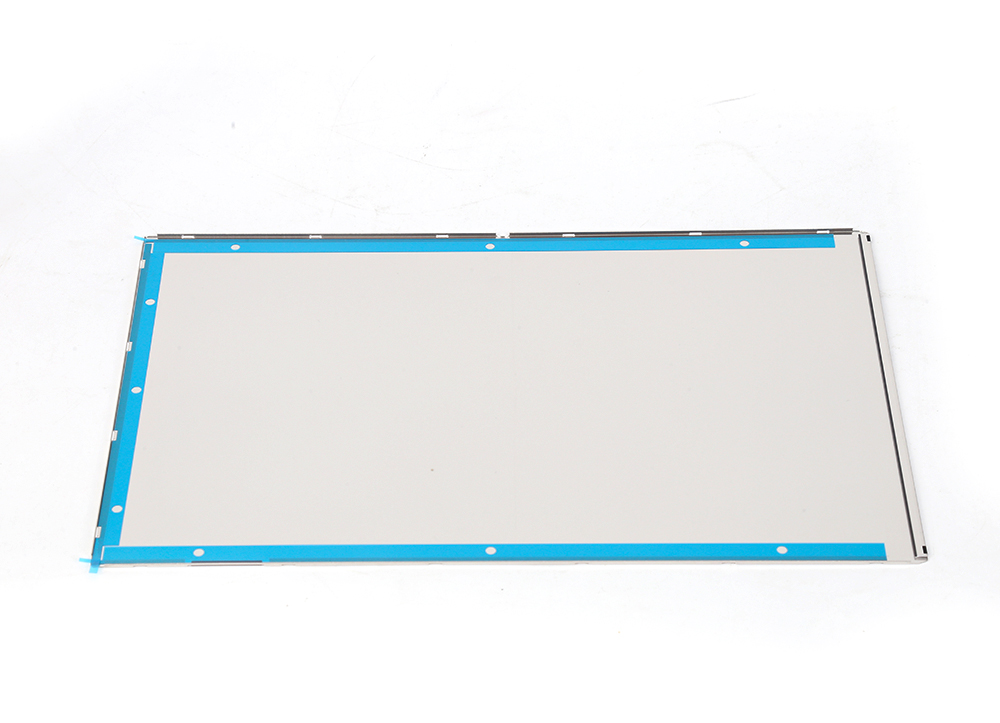

Hardware stamping refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure re...

Firstly, flexible transmission modeThe transmission mode of large CNC machining centers is very flexible. Belt type transmission can ensure that the entire mach...

Firstly, techniques for machining partsFirstly, operators need to pay more attention to some technical issues when machining parts. When working on CNC machinin...

Vertical CNC machining centers are also a machining method used in many fields nowadays. In order to help everyone understand this type of machining more, let&#...

From the current situation of CNC machining center simulation software, it mainly includes institutional systems, such as Frank system, Siemens system, and Siem...

1、 Pause instruction G04X (U)_/ P_ It refers to the tool pause time (feed stops, spindle does not stop), and the value after address P or X is the pause time. T...

When we perform thread machining on a CNC lathe, we usually use a cutting tool for cutting. When machining large pitch threads, excessive tool wear can cause si...

Related News

Related News·How to improve the quality of high -precision parts processing in the hardware processing plant ·What are the techniques of precision CNC lathe processing and fixture? ·Process display of precision mold parts processing ·Effectively controlling the temperature in the production process of precision hardware is also the · The Reason for Automatic Locking of CNC Machine Tools in CNC Computer Gongs ·How to deal with hand wheel failure during CNC processing? ·The main role of the connector contact plating using the electroplating process · What are the different types of hardware in hardware processing factories? ·Manipulating stamping hardware production and processing stamping parts caused by the way of turning ·Ensuring Product Quality in Profile Processing Centers